5 Ways to Improve Your Regulatory Compliance in the Biofuels Market

How to Leverage the Right Asset Integrity Management Software for Instant Regulatory Reporting

Posted on | by Metegrity Inc. | Category: Visions Enterprise, Regulatory Compliance, Asset Integrity Management

For the U.S. biofuels industry, regulatory compliance is critical but complex, involving various federal and state regulations. Ensuring compliance with these regulations is not only challenging but essential to avoid costly fines and operational disruptions. The key is leveraging the right asset integrity management (AIM) software system to streamline the process and ensure readiness for any audit.

The Challenge

Biofuel plants and associated facilities must comply with regulations set by regulatory agencies such as the Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), and Pipeline and Hazardous Materials Safety Administration (PHMSA). These regulators require specific information that must be easily accessible with specific details and demonstrable during audits.

A common challenge in the biofuels industry is the inability to demonstrate compliance due to siloed and disparate data. Reliance on paper files, spreadsheets, or unorganized electronic data can make it challenging to respond to audits confidently and in a timely fashion, even when actual practices meet compliance standards.

The Solution

To address these challenges and ensure compliance readiness, There are five effective changes you can implement using the right AIM software:

1. Data and Records Management

Approach:

- Utilize a single-source repository for regulatory reporting on equipment. This involves using a single AIM software for all sites and equipment types and maintaining all inspection data in the same searchable database.

Benefits:

- Leverage the data structures in Visions Enterprise® to systemize complex data management.

- The digital maintenance of all inspection and equipment data will improve efficiency in searching records and key information and in generating required regulatory information and responding to safety assessments.

2. Maintaining an Audit Trail

Approach:

- To support efficient operations and the specific needs of regulatory bodies such as the EPA, the AIM software system must store all equipment types, histories, and related data in a single, secure database with standardized data. By centralizing all necessary equipment information retrieving data is faster and more efficient.

Benefits:

- Centralizing all necessary equipment information, makes it quicker and easier to locate and retrieve data. Visions Enterprise® has been designed to comply with strict regulatory standards, the system ensures that all requested information is not only available but also verified and traceable, meeting the needs of any regulatory inquiry.

3. Equipment Risk Assessments

Approach:

- The utilization of AIM software with configurable risk models allows for qualitative, quantitative, and semi-quantitative assessments to determine the probability of failure (PoF) and the consequence of failure (CoF). Visions Enterprise® integrated Risk-Based Inspection offers centralized management of asset risk analysis, supporting both historical risk trending and future risk prediction, ensuring a comprehensive understanding of asset risk over time.

Benefits:

- This highly effective approach not only enhances the accuracy of risk assessments by incorporating various methodologies but also provides a robust platform for continuous risk management. The integration of RBI with Visions Enterprise® allows for a holistic view of asset risk, enabling organizations to track past performance and anticipate future risks, ultimately leading to more informed decision-making and proactive risk mitigation.

4. Configurable AIM Software

Approach:

- Choose user-configurable AIM software, allowing for the development of custom reports to meet different regulatory requirements, including those of OSHA and PHMSA.

Benefits:

- Regulator compliance data will be located and reported promptly during incident or audit situations where a fast response is required.

5. Security Considerations and Configurations

Approach:

- Ensure the AIM software includes fields for authorized inspector sign-offs and configurable security levels to ensure data integrity.

Benefits:

- Visions Enterprise® enhanced data security and accountability, ensures only authorized personnel can access and modify critical compliance data, thus meeting requirements such as OSHA’s Process Safety Management (PSM) standards.

Leveraging the Right AIM Software

Metegrity’s Visions Enterprise® software is designed around stringent regulatory standards, offers a complete, configurable solution for seamless regulatory compliance, protecting over $1,000 billion in assets across 1,350 facilities worldwide.

By implementing these strategies and utilizing advanced AIM software, biofuel companies can significantly enhance their regulatory compliance, ensuring they meet all jurisdiction requirements efficiently and effectively.

Contact us today to learn more about our comprehensive software solutions and start streamlining your asset management operations.

Key Features of Visions Enterprise®:

- 1. Comprehensive Data Management:

- Consolidate all aspects of an asset’s inspection history, including in-house and third-party reports, corrosion rates, repairs, and inspection schedules.

- 2. ISO 55000 Framework:

- Establish comprehensive maintenance and inspection data histories and analyze them per the ISO 55000 framework for consistency and accountability.

- 3. Regulatory Standards Compliance:

- Ensure the software can organize and present data according to major regulatory standards and allow for the configuration of reports as required.

- 4. Risk Assessments and Corrosion Control:

- Create risk assessments per API 580/581, and develop corrosion control documents and inspection plans.

- 5. Inspection Scheduling and Integrity Operating Windows:

- Schedule full assessment and external inspections, and employ Integrity Operating Windows (IOW) for early alerts on operating condition breaches.

- 6. Data Integration and Analytics:

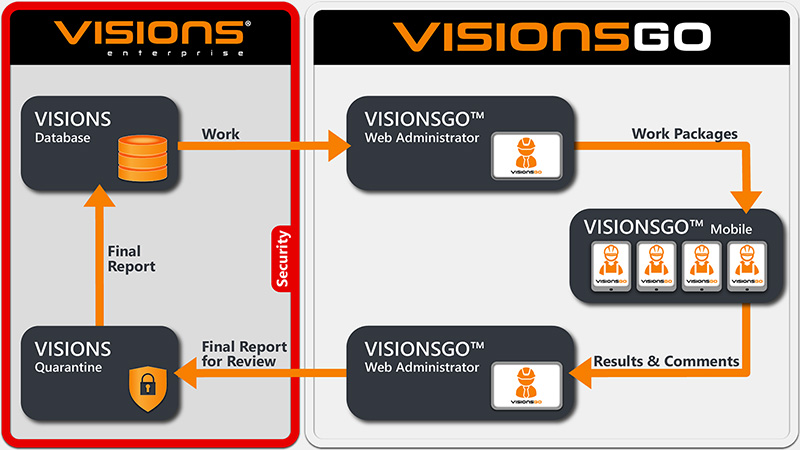

- The diagram below indicates Visions Enterprise® can Integrate equipment with worker and field data (via VISIONSGO™ mobility) to support ongoing daily inspections and periodic turnarounds, supporting comprehensive risk analysis and the generation of detailed reports with configurable dashboards and scorecards.

Press Releases

- 21 April 2021

Metegrity congratulates Mr. Suresh S. Bheema as a Subject Matter Expert at RBI 2021 4th International Conference - 06 October 2020

Metegrity Confirms New CEO, Martin Fingerhut - 17 September 2020

Metegrity Appoints Suresh Bheema as Senior Vice President - Asia Pacific Region - 17 December 2019

Visions Enterprise® 5 Achieves SAP-Certified Integration with SAP S 4HANA® - 19 November 2019

Metegrity Appoints New Chief Operating Officer, Martin Fingerhut

Latest Posts

- 22 January 2020

Metegrity CEO Discusses Petrochemical Cybersecurity at the 2019 G7 Summit - 30 September 2019

Join Metegrity at the 2019 OpEx Summit in Houston - 23 July 2019

The 13th Annual Maintenance & Reliability Symposium - 07 May 2019

Operational Excellence in Energy, Chemicals & Resources Summit 2019 - 05 March 2019

PMIES Expo 2019